Two-Way ER Valves

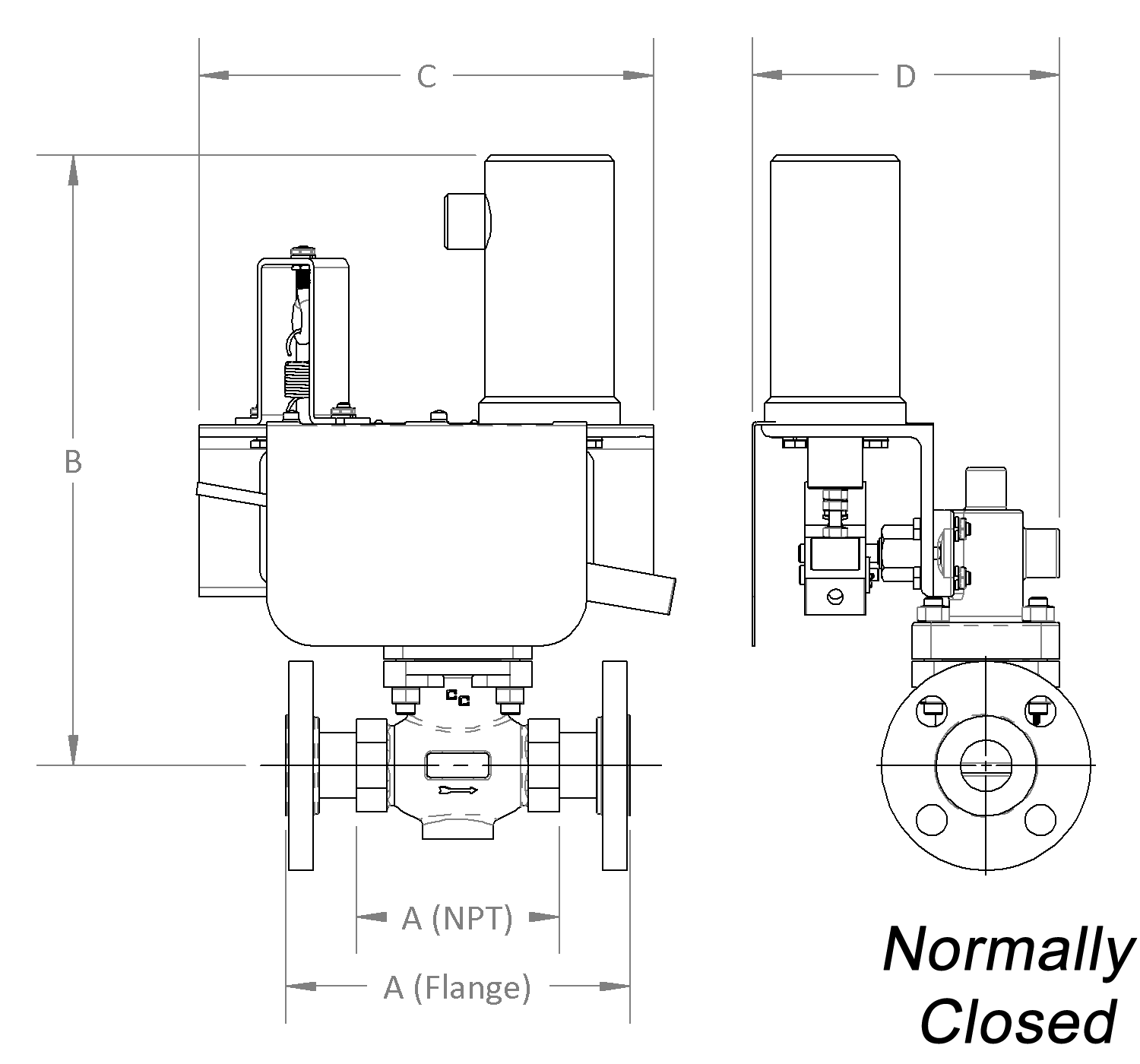

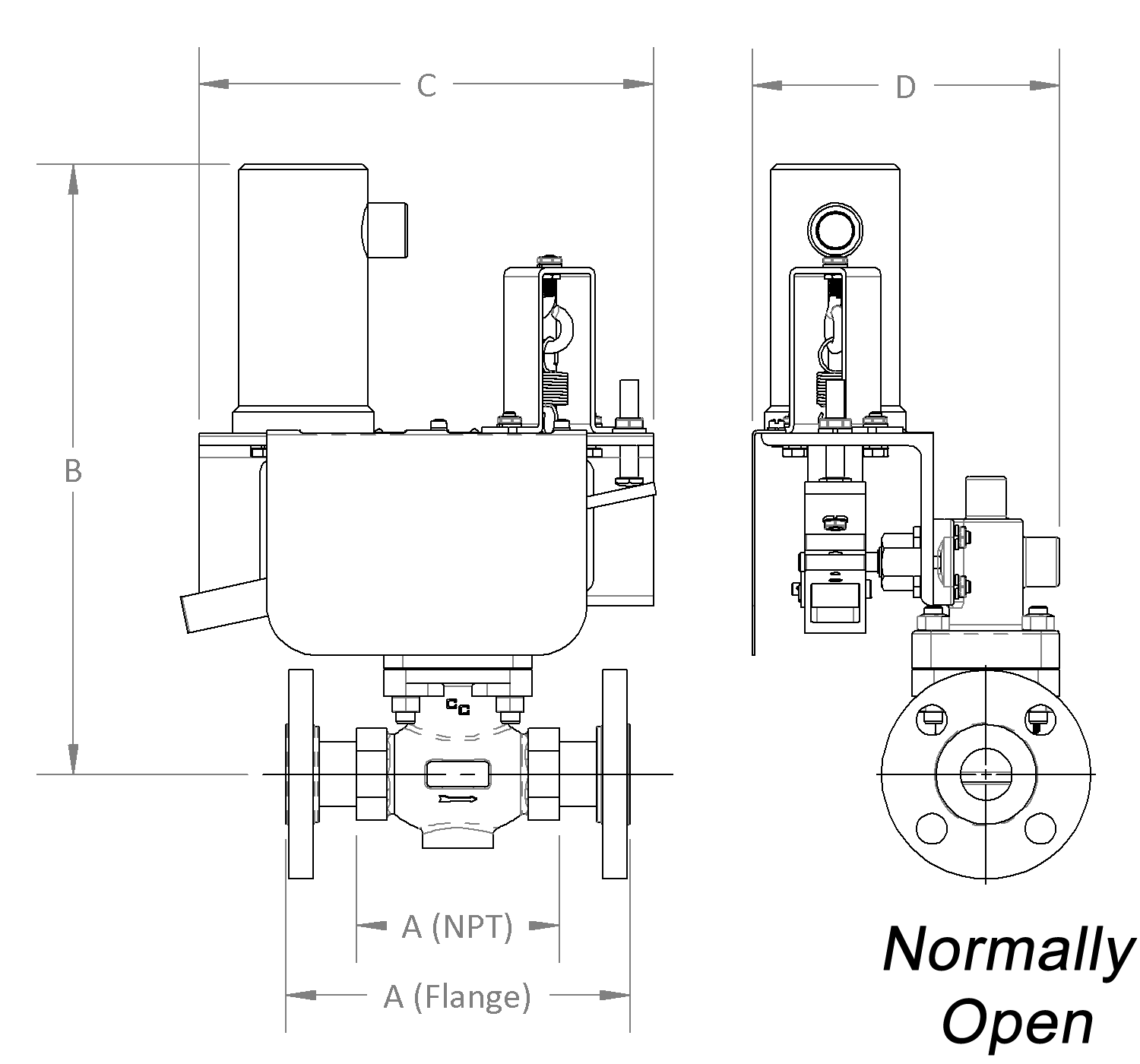

These rotary valves have one inlet & one outlet. The valve can be either fully open to allow maximum flow, or fully closed. Both Normally Open (fail open) and Normally Closed (fail closed) configurations are available. The valves are designed to stop fluid flow in the direction of inlet to outlet only. The flow direction is shown by an embossed arrow on the valve body casting.

No differential pressure required to open. All valves operate from zero to maximum pressure listed in table.

| Pipe Size (inches) |

Cv | Solenoid Series | Max. Operating Pressure Differential (PSIG) | Shipping Weight (lbs.) | Reference Dimensions (inches) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Direct Operated | Direct Operated, Pilot Assisted |

A NPT |

A 150#** |

A 300#** |

B | C | D | ||||||

| Normally Closed | Normally Open | Normally Closed | Normally Open | ||||||||||

| 1/2 | 5.6 | 400 | 500 | 400 | 2160 | 2160 | 13 | 3.25 | 5.50 | 6.00 | 12.0 | 9.3 | 6.3 |

| 800 | 2160 | 2000 | NA | NA | 18 | 13.8 | |||||||

| 3/4 | 8.5 | 400 | 125 | 100 | 1200 | 1200 | 15 | 3.50 | 5.75 | 6.50 | 12.2 | 9.3 | 6.3 |

| 800 | 800 | 720 | NA | NA | 20 | 13.9 | |||||||

| 1 | 11.9 | 400 | 50 | 50 | 1200 | 1200 | 18 | 4.13 | 7.00 | 7.25 | 12.4 | 9.3 | 6.3 |

| 800 | 375 | 300 | NA | NA | 23 | 14.1 | |||||||

| 1-1/2 | 46.4 | 400 | 10 | 10 | 500 | 450 | 25 | 4.94 | 7.63 | 8.25 | 13.1 | 9.3 | 6.7 |

| 800 | 75 | 75 | 1200 | 1200 | 30 | 14.8 | |||||||

| 2 | 67.2 | 400 | 5 | 5 | 200 | 200 | 45 | 6.00 | 9.00 | 9.63 | 14.5 | 9.5 | 9.6 |

| 800 | 25 | 25 | 720 | 720 | 50 | 16.3 | |||||||

| 3 | 152 | 800 | NA | NA | 275 | 275 | 78 | NA | 9.50 | NA | 17.2 | 9.5 | 10.3 |

| 4 | 215 | 800 | NA | NA | 150 | 150 | 135 | NA | 11.50 | NA | 20.3 | 11.3 | 12.0 |

Standard Sealing Is Class 2, Per ANSI/FCI 92-2-2001

*MOPD = Maximum Operating Pressure Differential Weights and dimensions are approximate and for reference only.

** ANSI Raised Face

Maximum Fluid Temperature 550° F

Two-Way ER Valves

Solenoid (Coil) Characteristics

Solenoid Coil:

Class H, Continuous Duty

36” long, 18 gage wire leads

Solenoid Enclosure:

Zinc Plated Carbon Steel

NEMA 4 (watertight)

NEMA 7 (explosion-proof)

NEMA 4X optional (Epoxy Coating)

400 Series Coil: Class I, Div I, Groups B - D

800 Series Coil: Class I, Div I, Groups B - D

Operating Temperature code: T2D

Ambient Temperature range: -20° C to +85° C

Conduit Connection:

1/2" NPT

AC voltages suitable with 50 and 60 Hertz

ER Valves have the following certifications:

| Solenoid Series | Voltage | Amps Inrush* | Amps Holding |

|---|---|---|---|

| 400 | 24V AC/DC | 18.0 | 1.0 |

| 48V DC | 12.0 | 0.6 | |

| 120V AC/DC | 5.0 | 0.3 | |

| 240V AC/DC | 4.0 | 0.1 | |

| 800 | 24V AC/DC | 27.0 | 2.0 |

| 48V DC | 25.0 | 1.0 | |

| 120V AC/DC | 16.0 | 0.5 | |

| 240V AC/DC | 8.0 | 0.2 |

Two-Way ER Valves

Options

S - Single Switch - Indicates when valve is in its energized position. Specifications can be found here.

X - Single Switch Explosion Proof - Indicates when valve is in its energized position. Specifications can be found here.

M - Dual Switch - Indicates when valve is in both its energized and de-energized position. Specifications can be found here.

Y - Dual Switch Explosion Proof - Indicates when valve is in both is energized and de-energized position. Specifications can be found here.

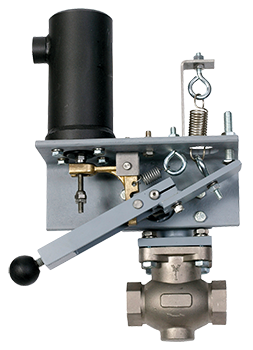

L - Locking Manual Override - Mechanically locks the valve in its energized position.

T- Terminal Box - Enclosure with the terminal strip attached to the coil. Customer is responsible for creating cable entry into the enclosure.

H - High Temperature - For valves running fluid hotter than 350°F.

V- Vertical Pipe - Valve is able to be mounted for verticle flow instead of horizontal flow.

--Other Options--

ETL - Solenoid meets the requirements for use in Class I, Division I, Groups B-D hazardous locations. More information about the 400 and 800 Series solenoid ETL listed mark is available here.

Oxygen Cleaned - Valve is cleaned of all internal contaminants to allow use for oxygen service.

Class 5 Leakage - Valve is tested for Class V leakage per FCI 91-2-2004 with air.

Class 5 Leakage with Helium - Valve is tested for Class V leakage per FCI 91-2-2004 with Helium. This is typically done for hydrogen service applications.

This list contains the options and features available for the ER series valve. ![]() Download ER Series - Model Number Breakdown

Download ER Series - Model Number Breakdown

* Not all combinations are possible. Please consult Clark Cooper before ordering.

Two-Way ER Valves

Solenoid Actuated

Solenoid Actuated two-way ER valves will fully actuate between open & closed positions when power is supplied or lost. This allows these valves to be fully automated. For example, a Normally Closed ER valve will be fully closed when no power is supplied & fully open when power is supplied.

| Solenoid Actuated | |

|---|---|

| Action | Actuates immediately when power is supplied, resets immediately on loss of power |

| Operation | Normally Closed (energize to open) Normally Open (energize to close) |

| Valves | ER15 (Direct Operated Pilot Assisted) & ER16 (Direct Operated) |

Emergency Trip

Emergency Trip valves are useful in applications requiring an emergency shutoff or dump. The valve actuates once, or 'trips', and remains in its tripped position until it is manually reset to its normal operating, or 'latched', position.| Trip When Energized | |

|---|---|

| Latch | Mechanical |

| Action | Trips immediately when power is supplied |

| Reset | Manual reset when power is off |

| Operation | Latched Open, trips closed Latched Closed, trips open |

| Valves | ER17 (Direct Operated Pilot Assisted) & ER18 (Direct Operated) |

| Trip At Specified Temperature | |

|---|---|

| Latch | Mechanical |

| Action | Trips when fusible link breaks at specified temperature (135°F, 165°F, 212°F, 286°F or 386°F) |

| Reset | Manual Reset, replacement of fusible link required |

| Operation | Latched Open, trips closed Latched Closed, trips open |

| Valves | ER19 (Direct Operated Pilot Assisted) & ER20 (Direct Operated) |

| Trip On Loss Of Power | |

|---|---|

| Latch | Electromagnetic (power must be supplied) |

| Action | Trips immediately on loss of power |

| Reset | Manual reset when power is on |

| Operation | Latched Open, trips closed Latched Closed, trips open |

| Valves | ER27 (Direct Operated Pilot Assisted) & ER28 (Direct Operated) |