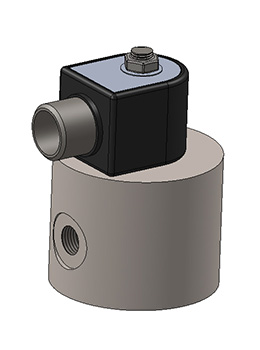

The EX40 Series

Features:

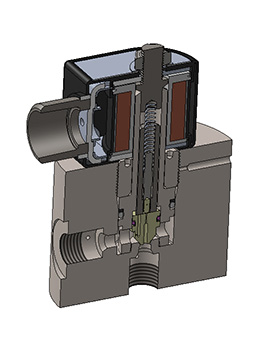

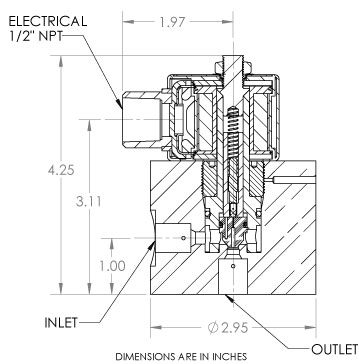

The reduced port EX40 is great for a wide range of media. This pilot operated valve has become a popular and effective choice in the emerging Hydrogen Dispensing market. The EX40 is also an excellent valve to control the flow of high pressure air, water, hydrogen, nitrogen, and other gases or light liquids compatible with materials of construction. The EX40 is the workhorse of our collection and offers a cartridge design that alleviates your demanding maintenance requirements. The EX40 requires a 100 PSIG minimum pressure differential between inlet and outlet for operation. The valve's simple design with few moving components have made the it a great choice for inlet pressures as high as 15,000 PSIG. The Normally Closed EX40 must be mounted upright and vertical. Filters are recommended for all applications.

Possible Media: (click each icon to learn more)

General Gases

& Light Liquids

Hydrocarbon

Fuels

Flammable

Gases

Hydrogen

Oxygen

Corrosives

Sea & Salt

Water

Viscous

Liquids

Steam

Cryogenics

The EX40 has the following certification:

EX40 Instruction Manual

ATEX Approved Coils Now Available

The EX40 Series

Construction

*Standard materialValve weight: 5.22 lbs |

|

||||||||||||||||||

The EX40 Series

Electrical (Coil) - DC Only

|

|||||||||||||||||||

PressureMaximum pressures shown are measured in PSIG

|

The EX40 Series

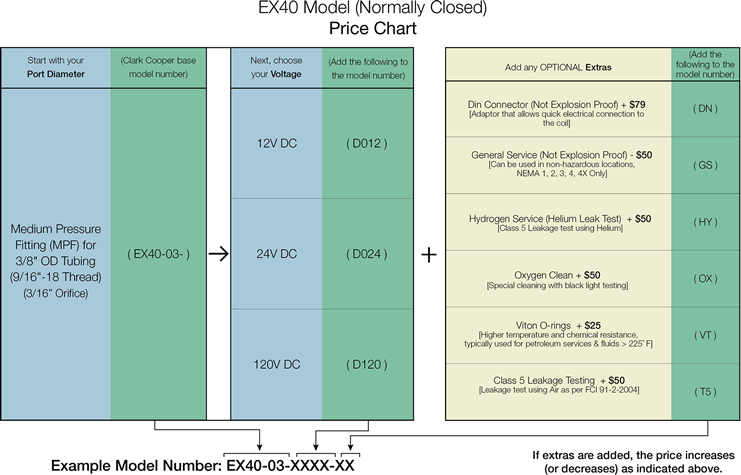

Possible EX40 Options:

Click each icon to learn more

72" Lead Length

Din Connector

Screw Terminal

General Service

Hydrogen Service

Oxygen Clean

Class V Leakage Testing

NEMA 4X

Stainless Steel Tags

Viton O-Rings

(for >225°F)

The following are standard on the EX40:

Explosion Proof

Stainless Steel Valve Body

22 W Coil

Options for our other valves include:

ETL Listed

Integrated Check Valve

Single Switch

¼ Tab (spade)

Tube Connector

SAE Port

Universal Mount

Cryogenic Cleaning

The EX40 Series

Standard delivery time: 10 weeks

Additional options or alternate materials may cause longer delivery times. Delivery time is for less than 5 valves.