The EP70 Series

Features:

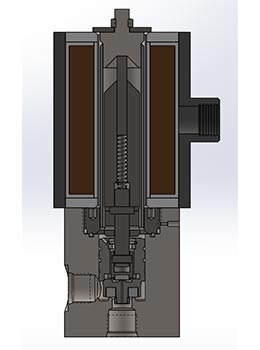

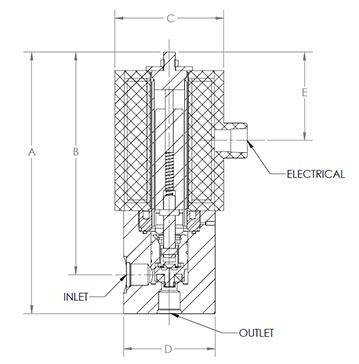

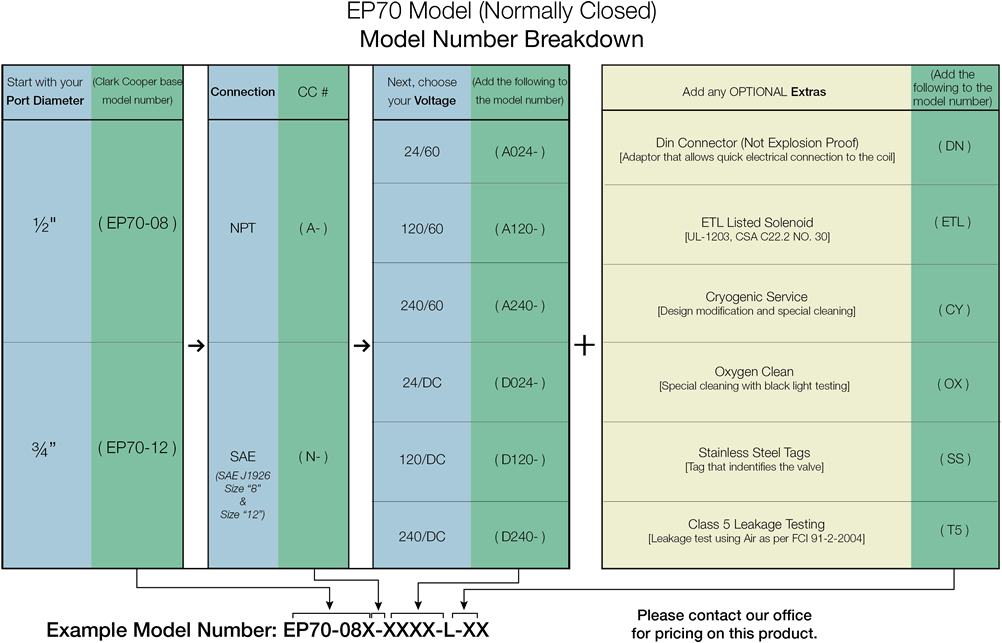

The powerful, full port EP70 is great for a wide range of liquid flow rates and temperatures. This pilot assisted, direct operated valve can be configured with a UL/CSA certified explosion proof coil for Class 1, Division 1, Group A-D locations. The EP70 has 1/2" NPT or SAE connections, and allows inlet pressures of up to 5000 psig. There is no minimum required pressure differential for opening/closing. The combination of a high power coil and larger internal bleed orifices, as compared to our other EH Series products, provides for less sensitivity to fluid viscosities and particulates. The EP70 can be used with water, fuel oils, flammable liquids and other liquids compatible with the construction materials. Filters are recommended for all applications.

Possible Media: (click each icon to learn more)

General

Liquids

Hydrocarbon

Fuels

Flammable

Gases

Hydrogen

Oxygen

Corrosives

Sea & Salt

Water

Viscous

Liquids

Steam

Cryogenics

How does this compare to other Clark Cooper Valves?

The EP70 Series

Construction

|

|

||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||

* Normally Closed Configuration Available Only

The EP70 Series

The EP70 Series

Possible EP70 Options:

Click each icon to learn more

72" Lead Length

ETL Listed Explosion Proof

Stainless Steel Tags

Class V Leakage Testing

NEMA 4X

Din Connector

SAE Port

Oxygen Clean

Cryogenic

The following are standard on the EP70:

Stainless Steel Valve Body

Options for our other valves include:

General Service

22 W Coil

Integrated Check Valve

Viton O-Rings

Screw Terminal

¼ Tab (spade)

Normally Open

Single Switch

Universal Mount

Tube Connector

The EP70 Series

"*If Explosion-Proof NEMA 7 Solenoid Coil is Required, ETL Option Must Be Selected Standard delivery time: 10 weeks

Additional options or alternate materials may cause longer delivery times. Delivery time is for less than 5 valves.