Unexpected valve failures disrupt flow, damage equipment, and cause downtime that no system can plan for. Corrosion, pressure stress, and temperature exposure quietly shorten a valve’s lifespan when the material does not match the application. What looks like a minor specification choice often becomes an expensive problem later.

Understanding how different materials perform under real operating conditions helps prevent premature wear and unnecessary replacements. This comparison explains how to choose between bronze and stainless steel solenoid valves.

Bronze Solenoid Valves

Bronze typically combines copper with tin and small amounts of other elements to improve strength and corrosion resistance. Manufacturers position bronze as a practical choice for water, air, light oils, and glycol blends in residential, HVAC, irrigation, and light commercial systems.

Cost and availability favor bronze for general service, and many catalogs list bronze bodies with NPT connections, Buna-N or EPDM seals, and standard temperature ratings that fit non-corrosive and mildly corrosive duty. Product lines such as the modified Magnatrol EV-series offerings include bronze options alongside stainless steel, with pressure ratings up to several hundred PSIG, depending on size and trim.

Advantages of Bronze Solenoid Valves

Cost-Effectiveness

Bronze offers a lower upfront cost than stainless steel while delivering reliable performance in applications involving water and other mild fluids. Its affordability allows for broader use in general-purpose systems without compromising basic reliability, making it an ideal option for projects with tight budgets or multiple valve installations.

Corrosion Resistance

The alloy resists atmospheric corrosion effectively, making it suitable for outdoor and rooftop installations when installers follow proper practices. Its natural resistance also helps reduce maintenance needs over time, keeping systems reliable even in exposed environments.

Simplified Installation and Maintenance

Bronze valves are compatible with common elastomers and standard coil voltages, simplifying inventory and installation. Maintenance is straightforward due to familiar thread standards, easy cleaning procedures, and the wide availability of replacement parts like coils and seal kits.

Durability in General Service

Bronze valve bodies can tolerate moderate particulate levels found in systems such as irrigation and cooling loops, especially when used with strainers. The material withstands occasional abrasion, allowing the valve to maintain a tight shutoff over its service life under typical operating pressures.

Cons of Bronze Solenoid Valves

Chemical Resistance

Bronze is not suitable for aggressive chemicals, strong acids, alkaline solutions, or high-chloride media such as seawater or brine. Exposure to these substances can accelerate corrosion, weaken the valve body, and shorten service life, making it a poor choice for harsh chemical environments.

Pressure and Temperature Limits

Bronze has lower pressure and temperature thresholds compared to stainless steel. It is not ideal for applications involving steam, superheated water, or high-pressure gases, which often require stainless steel for safety and durability.

Scale Buildup

Hard water can cause scale formation on valve seats and internals, reducing shutoff performance and increasing maintenance frequency if filtration or water softening is inadequate.

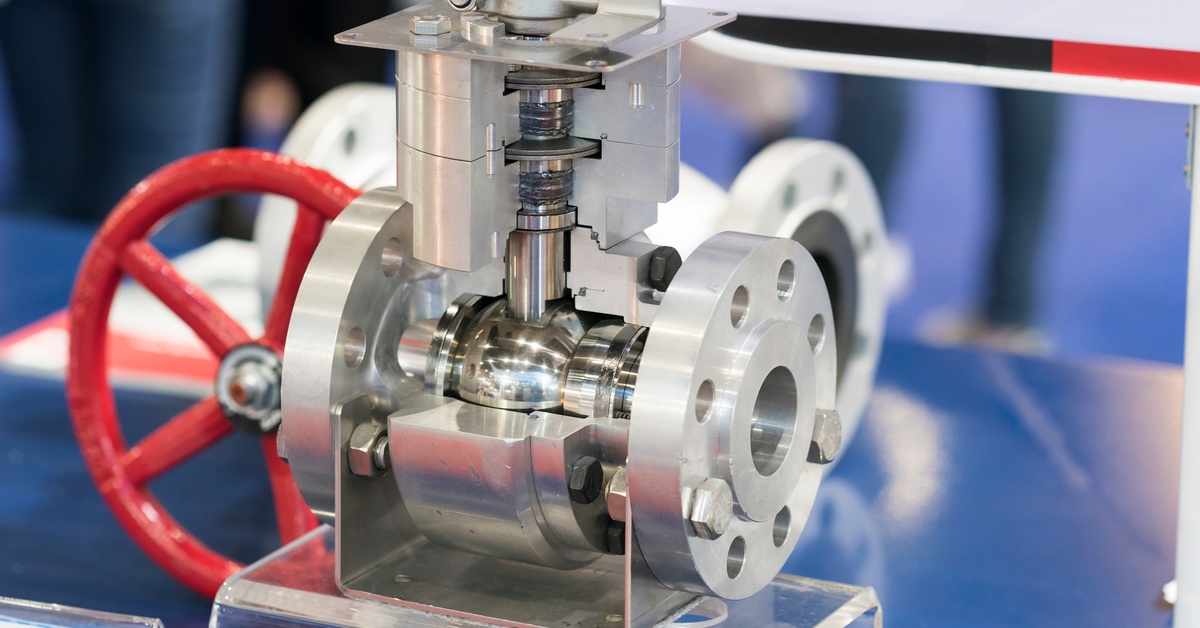

Stainless Steel Solenoid Valves

Stainless steel valve bodies typically use 304 or 316/316L alloys, which add chromium and molybdenum to resist corrosion across a wide range of fluids. Engineers choose stainless steel for caustic solvent, washdown, high-temperature, and chloride-exposed service.

Many industrial catalogs list stainless steel as the performance option because it offers high-pressure ratings and a broad temperature range. This combination of strength and corrosion resistance makes stainless steel ideal for demanding applications where reliability and longevity are critical.

Pros of Stainless Steel Solenoid Valves

Superior Corrosion Resistance

Stainless steel offers exceptional resistance to uniform corrosion, pitting, and crevice attacks across a wide range of environments. This includes exposure to salt spray, frequent washdowns, and various process chemicals. Options such as 316 and 316L grades offer enhanced resistance to chloride environments; they’re ideal for marine, food, and pharmaceutical applications where durability is crucial.

High-Pressure and High-Temperature Capability

Stainless steel valve bodies can withstand significantly higher pressures and temperatures than bronze counterparts. This makes them suitable for demanding applications such as steam service, hot-oil systems, and compressed-gas environments, as well as for aggressive clean-in-place (CIP) cycles.

Compliance and Sanitary Design

Sanitary models are available with features like tri-clamp connections, polished wetted surfaces, and FDA-compliant elastomers. These designs help facilities meet stringent regulatory standards, such as 3-A or FDA requirements.

Hazardous Environment Suitability

When paired with explosion-proof coil options, stainless steel bodies are ideal for hazardous locations. This combination meets NEC or ATEX classifications while resisting the corrosive atmospheres typical of dangerous areas.

Disadvantages of Stainless Steel Solenoid Valves

Higher Initial Cost

Stainless steel has a higher upfront cost than bronze, which isn’t always ideal for straightforward applications such as irrigation, HVAC, or low-pressure systems, where it does not provide significant performance benefits.

Potential for Galling

Stainless steel threads and fasteners can seize under pressure (galling). Prevent this by using anti-seize lubricants, mixing materials, or following proper torque specifications.

Chemical Compatibility Limitations

While highly corrosion-resistant, stainless steel isn’t universally compatible. It can degrade under specific conditions, such as chloride-stress cracking at high temperatures or exposure to strong reducing acids and halogenated solvents. In such cases, materials like Hastelloy or Monel may be better options.

Which One Is Best

When choosing between bronze and stainless steel solenoid valves, a few key factors determine the choice.

- Application: The first and most important factor to consider is the valve’s application. Bronze valves are better suited for low-temperature, low-pressure applications, while stainless steel valves can withstand high temperatures and pressures.

- Corrosion Resistance: Bronze has excellent corrosion resistance against seawater and brine solutions, making it ideal for marine applications. However, in harsh chemical environments, stainless steel is a better choice due to its superior resistance to various acids and alkalis.

- Cost: Generally, bronze solenoid valves are more affordable than stainless steel ones. This makes bronze valves a preferred option for budget-conscious applications.

- Durability: Both bronze and stainless steel are durable, but stainless steel offers a higher strength-to-weight ratio and greater resistance to wear and tear. Often, stainless steel valves are a suitable option for heavy-duty applications that require long-term reliability.

Considering these factors together will help you match the correct valve to your system’s specific needs. If your application involves moderate temperatures, standard pressures, and a tighter budget, bronze often delivers reliable performance without overspending.

On the other hand, if the system faces harsh chemicals, high pressures, or long-term heavy-duty use, stainless steel provides the durability and resistance needed to prevent costly downtime. Evaluating your priorities across the application, such as corrosion resistance, cost, and durability, ensures you select the material that keeps your system running smoothly.

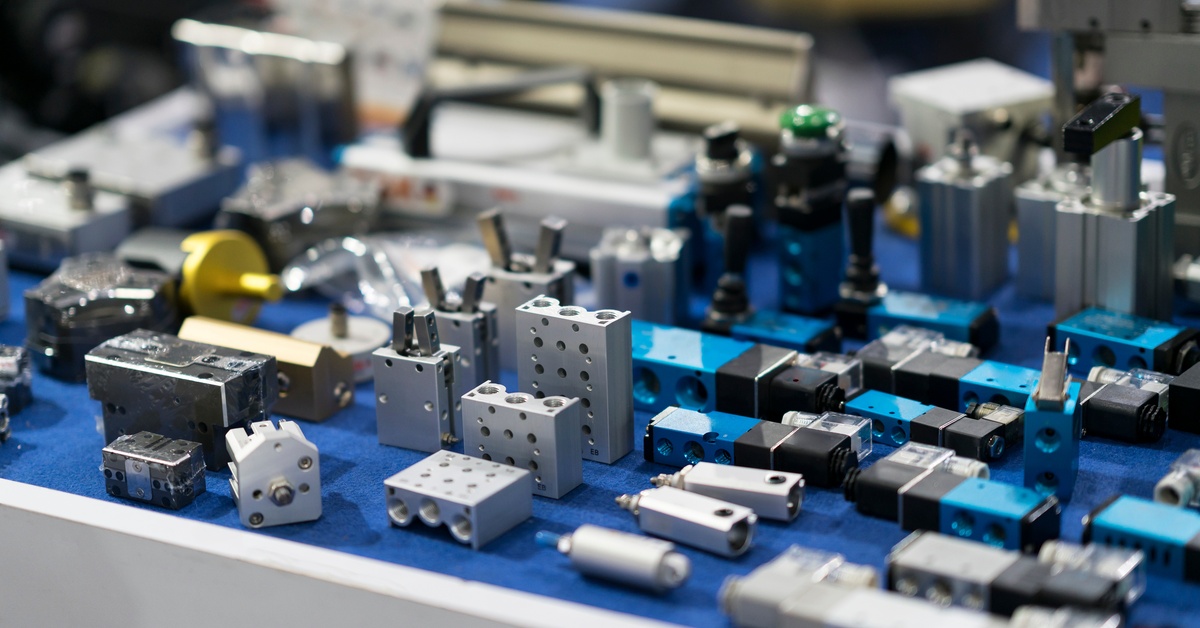

Buy Quality Valves

Neither material outperforms the other across every application. Bronze excels with clean water, air, light oils, and noncritical utility loops where cost matters and chemistry stays mild. Stainless steel earns the nod for chlorides, solvents, steam, higher pressures, and regulated spaces that demand sanitary surfaces or tough washdown performance.

Clark Cooper sells industrial solenoid valves that operate across various media and environments, with options in bronze and stainless steel. These valves are made with high-quality materials to ensure long-term reliability and performance in demanding industrial applications. With the right material in place, your solenoid valves will perform reliably, reduce maintenance headaches, and keep your systems running smoothly for years to come.

Leave a Reply