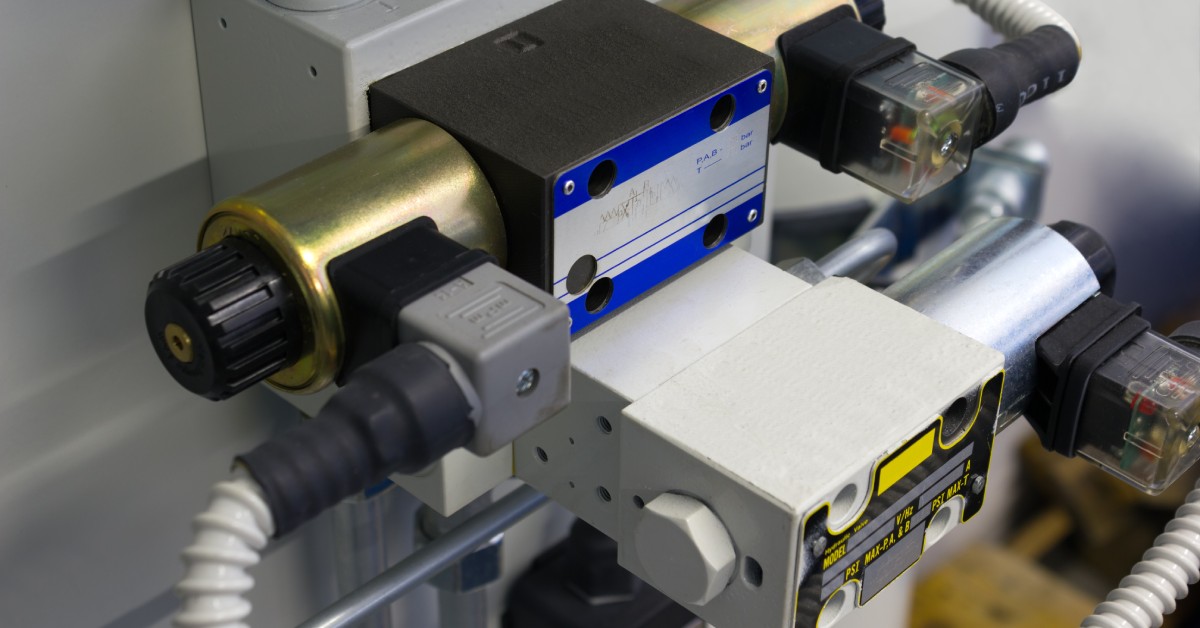

Solenoid valves often fail for reasons that are easy to miss. Systems run reliably until performance starts to slip without a clear cause. Valves begin to open more slowly, seals lose pressure, and flow becomes inconsistent. These issues rarely come from poor design alone. Temperature changes inside the system quietly create conditions that push components past their limits.

Understanding how temperature impacts solenoid valves helps explain why coils lose strength, fluids no longer behave as expected, and internal components struggle to move as intended. Properly managing temperature helps prevent leaks, downtime, and early valve failure.

Coil Resistance Changes

In a properly functioning system, the coil converts electrical energy into a magnetic field, and temperature directly affects this conversion. However, rising temperatures increase resistance, reduce current under a fixed supply, and weaken the magnetic field that pulls the plunger.

Cold conditions also create a distinct problem. Resistance falls, current increases, and the coil runs hotter during duty cycles that once seemed safe. In a hot boiler room, a coil already operating near its limit can lose enough magnetic strength that the valve never fully opens.

Fluid Viscosity Variations

Fluids thin as temperatures rise and thicken in the cold. Thinner fluid reduces drag, allowing the plunger and seals to move smoothly and helping marginal coils complete full strokes. On the other hand, thicker fluid increases resistance at the beginning of movement, making it harder for the plunger to seat or unseat accurately.

The added resistance slows response time and can even cause leaks. In hydraulic or fuel systems exposed to extreme temperatures, operators often use heaters to keep fluid viscosity within an optimal operating range.

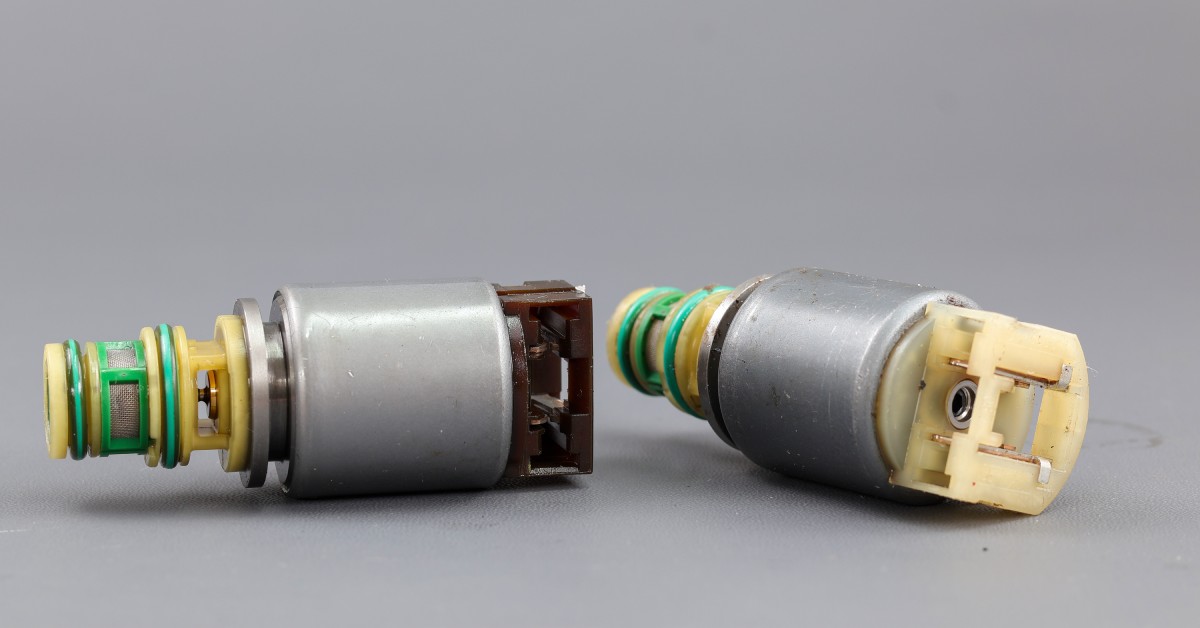

Seal Material Performance

Elastomer and polymer seals change hardness and elasticity with temperature. The cold stiffens many rubbers, preventing lips or O-rings from properly conforming to the seat, which can cause leaks, noisy chatter, and short strokes. High heat softens some compounds, leading to extrusion, permanent set, and premature wear.

Selecting materials such as FKM, EPDM, or PTFE based on the system’s actual operating temperature helps avoid these issues. It’s best to establish a clear operating range rating that provides a reliable baseline for performance.

Thermal Expansion of Components

Metals and plastics expand and contract with temperature, and solenoid valves rely on precise, repeatable fits to function correctly. A plunger that swells in a hot housing can bind and stall, while a seat that shifts even a few thousandths of an inch can cause leaks.

Moreover, plastic bodies and inserts deform more than steel, increasing the risk of failure in high-heat areas. For example, placing a plastic-bodied valve near a furnace can warp components enough by the end of a shift to completely throw tolerances off.

Response Time Variations

Response time measures in milliseconds, but even small temperature shifts can noticeably affect it. Cold mornings slow plunger movement as seals stiffen and fluids thicken. Likewise, hot days reduce actuation speed because the coil generates a weaker magnetic field under the same power supply.

In time-sensitive systems such as automated filling lines or high-speed pick-and-place cells, these delays disrupt timing and result in rejects. Reviewing temperature effects during hardware selection and control design ensures consistent valve performance.

Coil Insulation Degradation

Heat gradually degrades coil insulation, and once it breaks down, the circuit fails. Current can arc between windings, tripping breakers, or burning out the coil, often after intermittent operation, signaling the problem. Short-term heat spikes can also temporarily reduce insulation resistance, causing leakage currents before permanent damage occurs.

Alternatively, cold temperatures can make insulation brittle, increasing the risk of cracking or micro-fractures. Repeated heating and cooling further accelerate wear.

Pro Tip

In environments like steam lines, engine bays, and ovens, engineers select higher-temperature coil classes and manage duty cycles. The right valves also provide cooling paths to protect the coil and extend its service life.

Magnetic Properties of Core Materials

Core materials lose magnetic strength when pushed beyond their ideal temperature range. Some alloys lose permeability as the heat rises, reducing the force that moves the plunger. Extreme cold also alters magnetic behavior and changes hysteresis.

Outdoor valves exposed to both winter nights and summer afternoons require cores that maintain consistent performance across that range. A plunger with reliable force ensures the seat stays tight and timing remains steady.

Valve Sticking or Jamming

Cold air encourages condensation inside housings and bores, and that moisture can freeze unexpectedly. Ice grips the plunger like a vise, preventing it from moving. High heat dries light lubricants, leaves varnish, and allows debris to build up, all of which increase drag on moving parts.

Moreover, chemical vapors in hot environments can exacerbate the problem. A plunger with reliable force keeps the seat tight and the timing steady.

Electrical Component Stress

Temperature cycles strain connectors, wiring, grommets, and sensors that support the high-pressure electric valve. Copper expands and contracts, crimps loosen, and insulation can crack at bend points. Even a single loose spade terminal can cause intermittent trips that stump technicians.

You reduce risk by selecting components rated for the system’s operating temperature, routing harnesses with proper strain relief, and inspecting torque and insulation during scheduled maintenance. For example, a control panel in an engine bay may use high-temperature connectors and routed harnesses to prevent shorts during hot start-up and cold shutdown cycles.

Operational Pressure Limits

Materials that hold pressure at room temperature may fail under extreme heat. Elevated temperatures soften metals and plastics, reducing their safe working pressure. Cold makes some materials brittle, and shock loads can crack parts that once seemed robust.

Always verify the pressure rating at the actual operating temperature, not just the ambient nameplate value. Consider derating the valve or system for high-heat conditions, using materials rated for the extremes, and monitoring pressure during rapid temperature changes. These steps help prevent minor misreads from becoming blown seals or ruptured fittings.

Practical Tips for Managing Temperature Effects

Knowing how temperature affects solenoid valves helps you prevent downtime, leaks, and premature wear. These tips help ensure valves operate reliably across your temperature range.

Match Valve Temperature Ratings

Choose valves with published temperature ranges that fit your environment and fluid. Additionally, confirm both minimum and maximum real-world temperatures, including heat sources or drafts that could shift conditions.

Monitor Fluid Temperature and Viscosity

Use inline heaters, coolers, or recirculation to keep viscosity in the target range. Compare fluid viscosity curves from datasheets with your duty cycle, especially during startups.

Manage Coil Heat

Mount coils away from hot surfaces, add ventilation, and size power supplies to maintain proper voltage. In high-heat areas, choose higher-temperature coil classes.

Schedule Maintenance

Inspect coils for discoloration, smell for burnt odor, and measure resistance. Check seal hardness, tighten terminals, replace cracked boots, and reapply compatible lubricants after cleaning.

Protect Against Cold

Add insulation, trace heaters, or enclosures where frost risk exists. Purge moisture from pneumatic lines and route drains to prevent water ingress into housings.

Buy Quality Valves

Invest in valves built to handle the temperature extremes your system faces. Choose high-quality, durable solenoid valves from Clark Cooper to ensure reliable performance, reduce downtime, and protect your equipment. Proactively managing temperature effects and choosing the right valves ensures your system runs smoothly, efficiently, and reliably for years to come.

Leave a Reply