Burned-out solenoid coils do not typically fail without warning. Early indicators often include diminished performance, overheating, and system inefficiencies before a complete failure shuts down operations. Additionally, most solenoid valve coil failures are preventable and result from issues such as electrical mismatches, environmental stress, or internal mechanical problems. Use our expert guidance to understand why solenoid valve coils burn out, so you can prevent issues with your system.

Overvoltage

One common failure source is overvoltage. Each coil has a voltage rating specifying the electrical supply it can handle. When the supply voltage exceeds this rating, the increased current draw produces additional heat, accelerating insulation degradation and prematurely aging the coil windings.

Wiring errors in control panels or mismatched transformers can create sustained overvoltage, gradually damaging coil insulation over time. Verifying supply voltages during installation prevents this type of failure and protects the system from unnecessary downtime and additional component damage.

Undervoltage

Insufficient voltage can prevent the plunger from fully moving or delay actuation. When this happens, the valve remains engaged for longer than intended, a condition called extended energization, which increases current draw and can lead to overheating.

Buzzing or chattering sounds often accompany undervoltage and serve as early warning signs that something’s wrong. These symptoms are especially noticeable in applications with long cable runs or significant voltage drops caused by improper wire gauge or circuit design.

Incorrect Duty Cycle Rating

Every solenoid valve coil is designed for a specific duty cycle: intermittent or continuous. Continuous-duty coils handle extended operation, while intermittent-duty coils are intended for short bursts of activity. Running an intermittent-duty coil for prolonged periods causes heat to build quickly in the windings, eventually leading to coil burnout.

Misuse of intermittent coils is common in automation systems and HVAC setups, where they often operate longer than intended. Matching the coil’s duty cycle to the application’s operational requirements is a simple and effective way to prevent overheating and extend coil life.

High Ambient Temperature

The surrounding environment can also cause solenoid valve coils to burn out. High external temperatures increase the coil’s internal temperature, which can be driven by ambient conditions and nearby equipment. The extra stress reduces the thermal margin for insulation and accelerates its breakdown.

Always selecting coils rated for the specific temperature range of the application is essential. Choosing the right insulation class and ensuring proper ventilation and heat dissipation can significantly extend coil life and prevent premature failure.

Incorrect Coil Selection

Selecting a solenoid valve coil involves understanding voltage requirements, frequency compatibility, and application type. Missteps during coil selection often result in early failure. For example, alternating current (AC) and direct current (DC) coils operate differently and are not interchangeable. Similarly, frequency mismatches (such as installing a 50 Hz coil on a 60 Hz system) can cause performance inefficiencies and thermal failures.

International equipment retrofits carry extra risk because minor voltage mismatches can quietly strain coils over time, leading to premature wear and unreliable operation. Thoroughly checking coil specifications before installation helps avoid these problems and protects overall system performance.

Electrical Surges and Power Spikes

Solenoid valve coils are particularly sensitive to sudden electrical surges, which often occur when heavy-duty equipment starts up or when inductive loads cycle. These transient spikes create momentary overvoltage that rapidly heat the coil windings and gradually weaken insulation. Over time, this cumulative stress can lead to unexpected coil failure, sometimes long after the initial surge.

Installing surge suppression devices—such as surge protectors or voltage stabilizers—can absorb or divert these spikes, protecting the coil and other critical electrical components in the system. Without these safeguards, facilities may face repeated coil replacements, unplanned downtime, and higher maintenance costs.

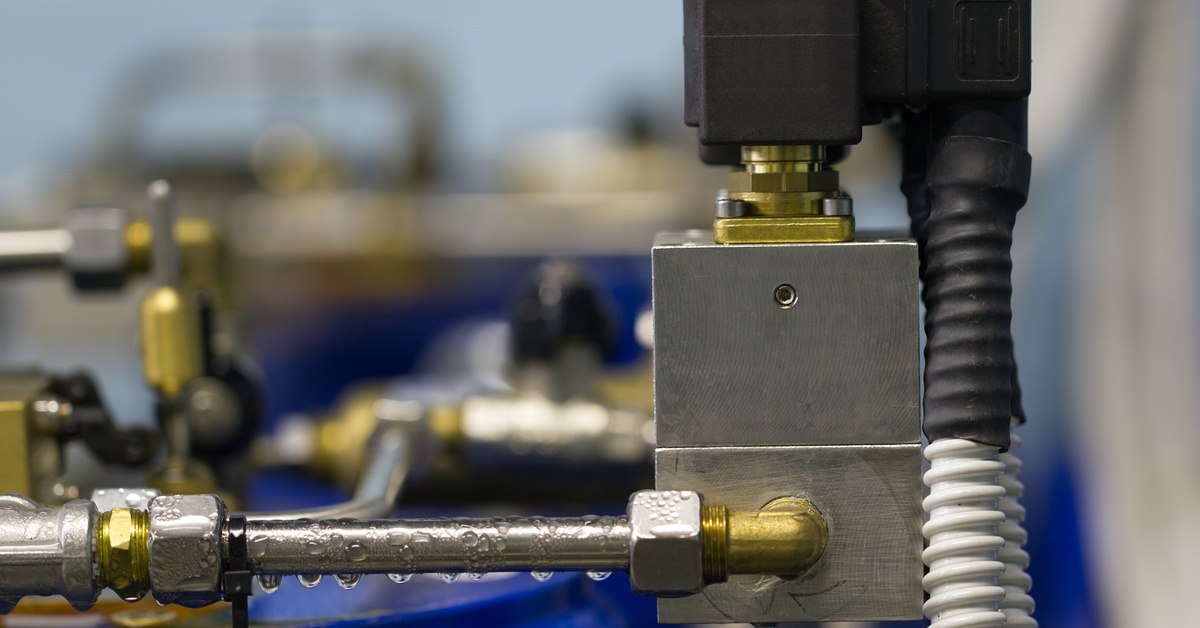

Poor Ventilation or Heat Dissipation

The physical arrangement of solenoid valves and their enclosures significantly impacts coil performance. Heat builds rapidly when valves sit too close together, airflow becomes restricted, or enclosures lack adequate ventilation. Improper heat dissipation leads to insulation breakdown and premature coil failure.

Ensuring adequate airflow and installing cooling solutions for IP-rated enclosures can prevent this often-overlooked issue. Simple measures can significantly improve heat dissipation. Spacing valves to allow natural airflow, adding fans or heat sinks, and avoiding stacked or crowded installations help keep coil temperatures within acceptable limits, protecting them from premature burnout.

Mechanical Valve Problems

Mechanical problems, such as sticking plungers, internal contamination, or corrosion within the valve assembly, forces the coil to work harder and run hotter. When the plunger encounters resistance, the coil compensates by working harder, generating additional heat as a byproduct.

Electrical faults often signal an underlying mechanical problem rather than a primary issue. By performing regular valve maintenance, operators can reduce coil strain and prevent avoidable failures before they escalate.

Moisture, Oil, and Contamination Ingress

Environmental exposure is a frequent cause of solenoid valve coil damage. Moisture, oil, dust, and other contaminants can penetrate the coil housing, degrading insulation and increasing the risk of electrical shorts or ground faults. Failed seals, worn gaskets, or improper washdown procedures often allow these substances to reach sensitive components.

To prevent contamination-related failures, select coils with appropriate IP ratings tailored to the specific operating environment, including wet conditions, chemical exposure, or heavy dust. Regularly inspecting and replacing seals, gaskets, and other protective components during routine maintenance helps catch damage before it compromises coil performance or causes unexpected system downtime.

Warning Signs Before Coil Burnout

Heat builds rapidly when valves sit too close together, airflow becomes restricted, or enclosures lack adequate ventilation. Solenoid valve coils typically display noticeable symptoms before complete failure, including the following:

- Buzzing or humming sounds

- Excessive surface heat

- Slow or unresponsive valve movement

- Intermittent functionality

- Burning odors

- Frequent tripping of fuses or breakers

Identifying these warning signs early allows maintenance teams to correct voltage, temperature, or mechanical issues before the coil fails completely

How to Reduce Solenoid Coil Failures

Proper installation, correct electrical matching, and routine maintenance reduce solenoid coil failures and extend system lifespan. Consider the following practices to improve the longevity and reliability of your solenoid coil:

- Match voltage and duty ratings accurately

- Manage ambient temperatures and provide proper ventilation

- Install surge suppression devices

- Maintain the mechanical components of the valve

- Regularly inspect seals, wiring, and system performance

These practices control heat buildup, stabilize the electrical load, and keep internal valve components moving freely, thereby preventing the conditions that lead to premature coil burnout.

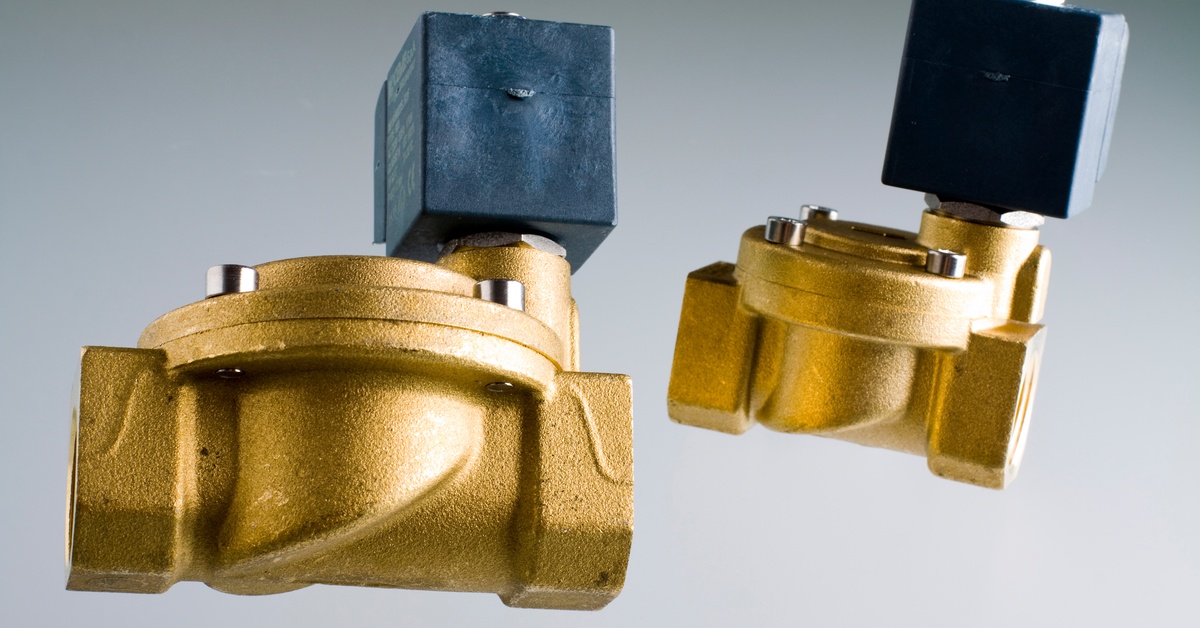

Invest In Quality Valves

By focusing on proper selection, installation, and maintenance, solenoid valve users can avoid unplanned downtime and costly repairs. Clark Cooper is a solenoid valve supplier that combines deep industry experience with engineered solutions for demanding applications. We offer a wide range of high-pressure valves used across multiple industries and can create custom products to meet specific requirements. Contact our team to discuss your application and find the right solution.

Leave a Reply