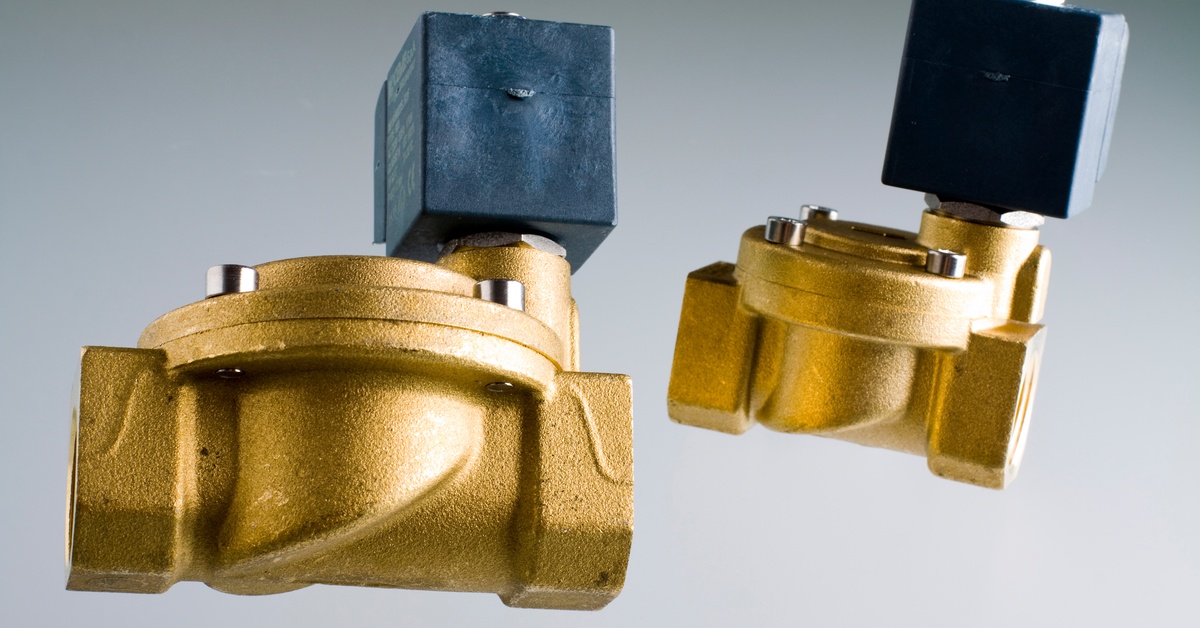

Engineers and industrial buyers often use solenoid valves and electric valves interchangeably, which creates confusion during specification. When teams misunderstand how each valve operates, they may select equipment that cannot meet performance demands. That mistake leads to unstable flow, premature wear, or expensive redesigns. Knowing the difference between solenoid valves and electric valves directly affects response time, pressure handling, and overall system reliability.

(more…)Author: Clark Cooper

-

9 Main Features of High-Pressure Solenoid Valves

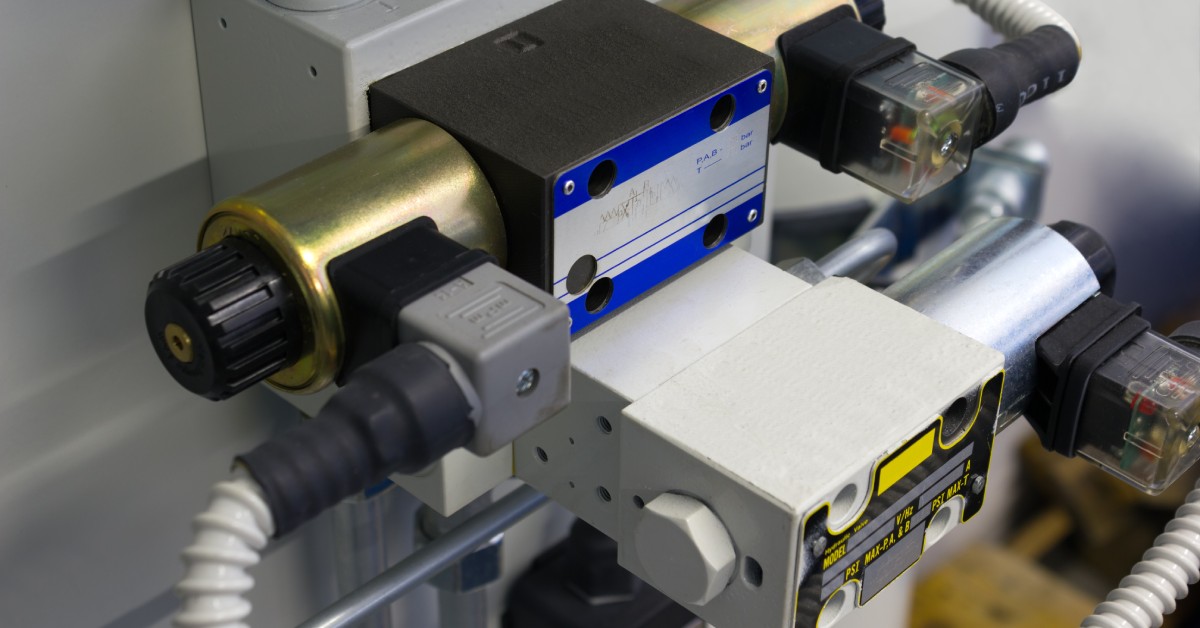

In industries where systems operate at elevated PSI, valve performance directly impacts safety, efficiency, and uptime. Engineers in oil and gas, aerospace, marine, and power generation rely on precise flow control to manage demanding processes. When pressure increases, even small design weaknesses can lead to leakage, delayed response, or premature wear.

(more…) -

An Essential Guide to the Different Types of Rotary Valves

Rotary valves sit at the heart of bulk material handling and pneumatic conveying, where flow control, pressure integrity, and product protection matter on every shift. Operators encounter powders with very different properties, along with changing temperatures, pressures, and hygiene or safety requirements.

(more…) -

The Importance of Emergency Marine Trip Valves

Marine systems operate under heat, vibration, and high pressure, and even small failures can escalate quickly. A ruptured hose, a compromised intake, or a leaking fuel line can flood compartments, spray fuel, and fill the engine room with smoke in seconds. Alarms sound, and crews have only moments to act before damage spreads.

(more…) -

Bronze vs. Stainless Steel Solenoid Valves: Which To Choose?

Unexpected valve failures disrupt flow, damage equipment, and cause downtime that no system can plan for. Corrosion, pressure stress, and temperature exposure quietly shorten a valve’s lifespan when the material does not match the application. What looks like a minor specification choice often becomes an expensive problem later.

(more…) -

What Causes Solenoid Valve Coils To Burn Out?

Burned-out solenoid coils do not typically fail without warning. Early indicators often include diminished performance, overheating, and system inefficiencies before a complete failure shuts down operations. Additionally, most solenoid valve coil failures are preventable and result from issues such as electrical mismatches, environmental stress, or internal mechanical problems. Use our expert guidance to understand why solenoid valve coils burn out, so you can prevent issues with your system.

(more…) -

9 Signs Your Rotary Valves Are Wearing Out

Rotary valves sit at the heart of bulk material handling, pneumatic conveying, and dust-collection systems because they meter material while separating pressure zones. Tight internal clearances, smooth rotor tips, and healthy bearings keep discharge predictable and keep air under control. Wear introduces leakage, friction, and erratic flow, which strain blowers, degrade product quality, and disrupt downstream equipment. Teams that track early indicators avoid surprise failures and schedule service on their terms, not the valve’s.

(more…) -

The Effects of Temperature on Solenoid Valves

Solenoid valves often fail for reasons that are easy to miss. Systems run reliably until performance starts to slip without a clear cause. Valves begin to open more slowly, seals lose pressure, and flow becomes inconsistent. These issues rarely come from poor design alone. Temperature changes inside the system quietly create conditions that push components past their limits.

(more…) -

2-Way vs. 3-Way Valves: Which Is Best for Your Needs?

Choosing the correct valve for your system can feel surprisingly complicated. With options like 2-way and 3-way valves, it’s easy to get overwhelmed. Making the wrong choice can lead to inefficiency, increased costs, or even system failure. The stakes are high: the wrong valve can cause uneven fluid flow, pressure imbalances, or unnecessary wear on pumps and pipes, resulting in downtime and expensive repairs.

(more…) -

The Only Rotary Valve Troubleshooting Guide You Need

Rotary valves meter and isolate bulk solids in pneumatic conveying and dust collection. They regulate feed rate, maintain pressure differentials, and protect downstream equipment. However, a small misalignment or a minor leak can snowball into lost throughput and worn parts.

(more…)