High-pressure solenoid valves control the flow of fluids and gases in systems that demand precision. These valves can withstand extreme pressures and temperatures, making them suitable for aerospace, healthcare, and power generation, as well as other industries. Read on to learn about the common applications for high-pressure solenoid valves across sectors.

Aerospace Industry

In the aerospace industry, high-pressure solenoid valves benefit performance and safety in both aviation and space exploration by controlling fluids and gases within hydraulic systems. This flow powers essential functions, such as landing gear deployment and retraction, flight control surfaces, and braking systems. Likewise, being able to operate valves despite immense pressure and extreme temperature changes increases safety for everyone on the flight.

Furthermore, numerous aerospace-grade pneumatic controls utilize high-pressure solenoid valves, including engine start systems, thrust reversers, and cabin pressurization systems. In engine start systems, these components deliver precise bursts of fuel to ensure smooth ignition, even when faced with intense vibrations and temperature changes.

Likewise, for thrust reversers and cabin pressurization systems, they offer the quick responsiveness needed to keep everything running safely and effectively. These parts ensure reliable operations in the demanding conditions of aerospace environments.

Oil and Gas Industry

The oil and gas industry often uses high-pressure solenoid valves in wellhead control systems, gas transmission pipelines, and offshore drilling platforms. In these applications, the valves manage the flow of volatile substances under extreme pressures and temperatures.

In wellhead “Christmas tree” assemblies, high-pressure solenoid valves play a crucial role in controlling the flow of oil and gas from the well. This allows operators to effectively manage production and perform shutdowns whenever necessary. Built to last, these valves use durable, corrosion-resistant materials, which enable them to handle the harsh chemicals and abrasive substances typically found in extracted hydrocarbons.

High-pressure solenoid valves are also key parts of emergency shutdown (ESD) systems, which quickly isolate sections of a pipeline in the event of a leak or rupture. By activating the emergency stop, workers prevent environmental damage and protect themselves and their peers. They also function as actuators for larger valves, using hydraulic or pneumatic pressure to open or close main pipeline valves from a remote location.

Industrial Fields

In manufacturing, experts use high-pressure solenoid valves in high-pressure water jet cutting machines, where they precisely control the flow of water pressurized to extremely high levels. This control allows the water jet to cut through hard materials like metal and stone with incredible accuracy, making it a versatile tool for fabricating complex parts. High-pressure cleaning equipment—used for jobs like paint stripping and industrial surface prep—depends on these valves to safely and effectively control powerful water streams.

High-pressure solenoid valves quickly release fire-extinguishing agents, such as water, foam, or gas, in automated fire suppression systems, containing fires before they cause significant damage or pose a risk to lives. Their fast response time and reliable operation make them essential components in fire protection systems in commercial buildings, industrial facilities, and even vehicles.

Power Generation Industry

In the power generation industry, high-pressure solenoid valves manage high-pressure steam and other fluids, maximizing energy output and ensuring plant safety. They are essential in power plants, controlling steam flow from boilers to turbines to improve efficiency, enhance safety, and minimize waste. Additionally, the performance of a high-pressure solenoid valve directly impacts the plant’s ability to generate electricity reliably and cost-effectively.

The operational integrity of key power plant equipment also relies on these valves. In boiler feedwater systems, solenoid valves regulate the water supply to the boiler, ensuring a stable water level that supports safe and efficient steam production. Turbine control systems use high-pressure solenoid valves to manage lubricating oil and hydraulic fluids, providing smooth and uninterrupted operation.

Water Treatment Industry

Water treatment is another common application for high-pressure solenoid valves, as precise fluid control is essential for both efficiency and regulatory compliance. These valves assist in managing the flow of water, chemicals, and other fluids at various stages of treatment, such as filtration, chemical dosing, and disinfection.

For example, in the dosing process, solenoid valves control the amount of chemicals—such as chlorine or coagulants—that enter water. They’re also key in reverse osmosis systems, where they help balance high pressures and support energy-efficient operation.

Additional Applications

High-pressure solenoid valves offer versatility that enables their use in a variety of specialized applications beyond traditional heavy industries. Some of the other ways industries use these types of solenoid valves include:

Hydraulic and Pneumatic Systems

High-pressure solenoid valves play an integral role in the operation of hydraulic and pneumatic systems, commonly used in industries like manufacturing, construction, and transportation. These systems rely on controlled fluid or air pressure to power machinery, perform precise movements, or maintain stable operations.

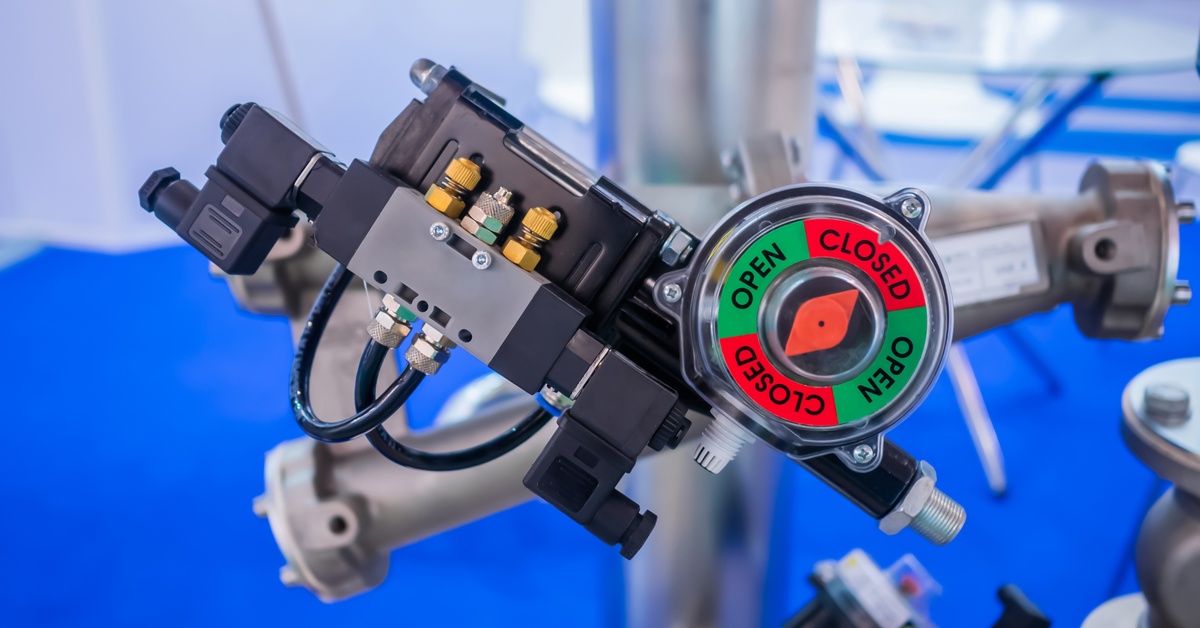

Hydraulic systems use liquid, usually oil, to create pressure, while pneumatic systems rely on compressed air. In both setups, solenoid valves act as control points, directing the flow by opening, closing, or adjusting the passage as needed. This precise control helps the systems run efficiently and respond to commands.

Medical Equipment

High-pressure solenoid valves help control the flow of fluids or gases. These valves are integral to ventilators, anesthesia machines, and diagnostic tools, where accuracy and reliability are essential for patient safety and effective treatment.

In ventilators, they regulate the balance of oxygen and air to maintain the right pressure levels for steady breathing support. Additionally, anesthesia machines rely on high-pressure solenoid valves to deliver the exact gas mixture patients need during surgery. Even in diagnostic tools like blood analyzers, solenoid valves handle tiny amounts of fluid with accuracy, ensuring dependable test results.

Food and Beverage Industry

High-pressure solenoid valves play a crucial role in controlling the flow of fluids and gases in various processes such as bottling, carbonation, and pasteurization. Their precise operation is essential for maintaining product quality, consistency, and safety.

In bottling, high-pressure solenoid valves make sure each container gets the right amount of liquid, which speeds up production and cuts down on waste. They also reduce the flow of CO₂, so drinks like soda and sparkling water come out with just the right amount of fizz. Furthermore, during pasteurization, high-pressure solenoid valves control how fluids move through heat.

Partner With the Best

As a high-pressure solenoid valve manufacturer, Clark Cooper delivers reliable solutions for extreme pressures and temperatures. Explore our comprehensive product line and discover the ideal valve for your specific needs. Contact our technical sales team today to explore customized solutions tailored to your specific operational challenges.

Leave a Reply