When an unreliable solenoid valve manufacturer fails to deliver, the consequences can disrupt your operations. Faulty solenoid valves lead to leaks, performance failures, and costly downtime that nobody wants to waste money on. Whether you’re managing a manufacturing plant, a processing facility, or specialized equipment, your business depends on quality and precision.

Working with a solenoid valve manufacturer determines whether your equipment runs smoothly or breaks down at the worst possible moment. However, the market has countless companies for you to consider, so making the right choice comes down to evaluating your options. Our guide explains how to choose a reliable solenoid valve manufacturer.

Compare Costs vs. Value

The price of your solenoid valve will vary among manufacturers, and cheaper products often mean lower-quality parts. That said, the most expensive option isn’t always the best either. Instead, look for competitively-priced options sold by manufacturers with high ratings.

Additionally, value considerations include support services, delivery reliability, and warranty coverage. Manufacturers who provide comprehensive support reduce your internal costs for technical assistance, troubleshooting, and spare parts management. These services add significant value that justifies premium pricing.

Consider these key factors when evaluating manufacturer value:

- Product reliability and expected service life

- Technical support quality and availability

- Warranty coverage and claims process

- Delivery performance and lead times

- Engineering support for custom applications

Balancing cost and value is essential for long-term operational efficiency. A solenoid valve with a higher upfront cost but longer service life and strong support can end up being more cost-effective than cheaper alternatives. By considering these factors, you make an investment that ensures dependable performance and minimizes unexpected expenses.

Check Their Industry Experience

Years of manufacturing experience have led to more reliable products and services from the company. Experienced manufacturers have encountered various challenges and learned how to refine their processes for the best solution. Industry experts understand how different environments affect solenoid valve performance and can recommend the best products for your specific needs.

Moreover, solenoid valve manufacturers with a long-standing reputation are likely to have higher-quality products. Their longevity suggests they have built strong relationships with suppliers, invested in proper equipment, and developed efficient quality control systems.

Technical Expertise Matters

Experienced technical teams can recommend appropriate solenoid valve specifications based on your operating conditions, media compatibility, and performance requirements. They understand how different factors interact to affect solenoid valve performance and can suggest modifications that improve reliability.

Moreover, manufacturers with strong technical capabilities often offer custom engineering services for unique applications. Their teams can modify existing designs or create entirely new solutions when standard products don’t meet requirements. This flexibility is particularly valuable when your applications operate under unusual conditions or have limited space constraints.

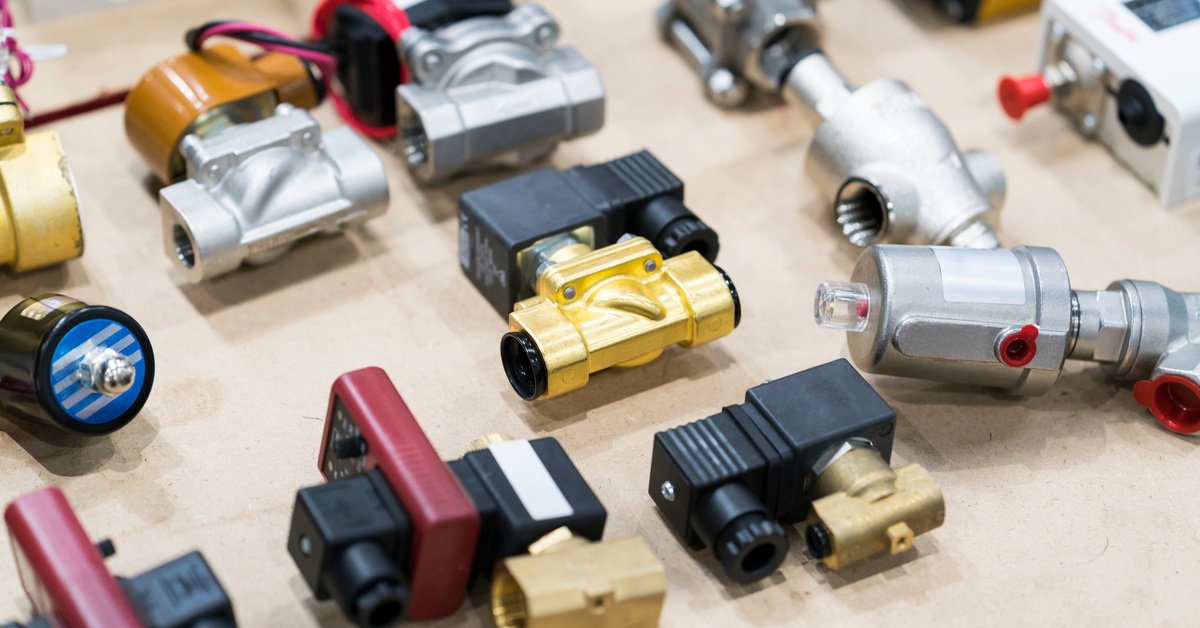

Analyze Their Product Range

Another tip for choosing a reliable solenoid valve manufacturer is to evaluate the components they have available. Manufacturers who offer solenoid valves in multiple materials, pressure ratings, and configurations understand diverse application requirements and can recommend optimal solutions. This variety suggests they have invested in different production capabilities and maintain expertise across multiple valve types.

Companies with extensive catalogs can supply different solenoid valve types from a single source, simplifying procurement and support relationships. This consolidation reduces vendor management overhead and often leads to better pricing through volume agreements.

Pro Tip

It isn’t necessarily a bad thing if a company has limited product offerings; they may specialize in a narrow market. Note that you may need to rule them out if their solenoid valves don’t align with your needs.

Evaluate Product Quality Standards

Companies with rigorous testing procedures catch defects before products reach customers, reducing the likelihood of field failures. These manufacturers typically document their quality processes and can provide detailed explanations of their testing methods. When solenoid valves meet performance expectations, they’re less likely to leak or malfunction once installed.

Follow these tips to assess a manufacturer’s adherence to quality standards:

Verify Certifications

The manufacturer you work with should have ISO 9001 or CE compliance certifications, as they demonstrate that the manufacturer follows established quality management principles and continuously monitors its processes.

You may also need to obtain additional certifications, particularly if you work in a specialized industry. For example, if your business is in the medical field, manufacturers need FDA approvals, while companies serving the aerospace industry must meet AS9100 standards.

Ask About Testing Protocols

A reliable manufacturer should follow rigorous testing protocols before releasing their products to the public. Ask the manufacturer to provide details about how they test their solenoid valves. Do they simulate real-life operating conditions, such as temperature extremes, pressure cycles, and corrosive environments? Knowing their approach to testing will give you insight into how likely their products are to perform well over time.

Request Sample Products

Never skip the opportunity to evaluate sample products firsthand. Look for indicators of quality, such as smooth finishes, precise dimensions, and compatibility with your system requirements. Test the sample in conditions similar to your operational environment to assess its performance under pressure, resistance to wear and corrosion, and usability.

Read Customer Reviews

Third-party reviews provide unfiltered insights into manufacturer performance and customer satisfaction levels. Look at independent platforms and industry forums for honest feedback from users sharing their experiences with specific products and services. These reviews reveal patterns in performance, delivery, and support that company testimonials might not disclose.

Customer feedback highlights both strengths and weaknesses that affect daily operations. Reviews often mention delivery reliability, product durability, and responsiveness to technical questions or problems. As you read reviews, note commonalities in positives and negatives so you can compare all your manufacturer options.

Inspect Their After-Sales Support

Help from the manufacturer shouldn’t end when you purchase the solenoid valve. Strong manufacturers provide multiple support channels, maintain adequate spare parts inventory, and respond quickly to technical questions or warranty claims. Their support teams understand both their products and common application challenges.

Ongoing support from the manufacturer can include things such as:

- Warranties

- Routine maintenance

- Repairs

- Technical support

- Spare parts availability

- Training programs

Ideally, you want to buy from a manufacturer who strives to form a partnership with their buyers. These manufacturers invest in their customers’ success and go above and beyond to ensure that their products meet their customers’ needs.

Contact Us

Explore Clark Cooper’s selection of high-quality solenoid valves designed for reliability and performance. If you need help selecting the correct component, our customer support team can help you locate the item required or discuss tailored custom options.

We understand that choosing the right solenoid valve manufacturer is a big decision that shapes the efficiency of your entire operation. Take time to evaluate your options and prioritize long-term value.

Leave a Reply